Ramping up production

Staffing done right in a shiftwork operation If your company is among those who experienced a demand surge due to recent disruptive changes and therefore, you want to swiftly ramp up your production β you are going to need a plan of action. How do you take the first step in the design of matching … Continue reading “Ramping up production”

Characteristics of Effective Shift Schedules

When considering alternative shift schedules, you should evaluate how they affect your cost structure and whether they make your operation easier to manage. At a minimum, an effective schedule should: Keep your best and/or most expensive equipment productive, i.e. maximize your equipment utilization. Provide continuous coverage in areas that have significant start-up and shutdown costs. … Continue reading “Characteristics of Effective Shift Schedules”

How to Manage Variable Workloads

How to maintain the right amount of coverage and minimize the costs by Dan Capshaw & Bruce Oliver- Shiftwork Solutions LLC Does the demand for your companyβs product(s) follow a seasonal pattern or exhibit other periodic variations? As long as the changes in demand are not βpermanent,β there is no reason to hire enough employees … Continue reading “How to Manage Variable Workloads”

Are Maintenance Workers Really Different than Other Shiftworkers?

By Bruce Oliver and Dan Capshaw, Shiftwork Solutions LLC Many maintenance managers will tell you their workforce is different than other shift workers β that their attitudes and behaviors are not the same. Recognizing, understanding, and accounting for how maintenance personnel evaluates shift schedules are essential to finding a schedule that will satisfy their needs … Continue reading “Are Maintenance Workers Really Different than Other Shiftworkers?”

When should Management consider a Shift Schedule Unsustainable?

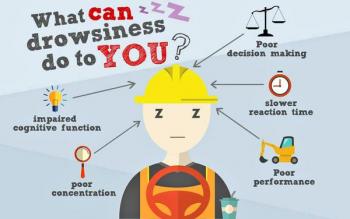

Most production managers have been there. Demand is higher than their ability to supply β without the use of overtime. The logical, and possibly, the best solution in the short-run is to go ahead and produce more by using overtime hours. What is going on when you ramp up overtime? What are the costs? What … Continue reading “When should Management consider a Shift Schedule Unsustainable?”

12 Symptoms You May Not Know Are Connected

Business Leaders and Managers regularly scan the health of their organizations. Even the most well-run businesses are embedded in a complex eco-system, one with many influencing factors. Certain sub-optimal signals and symptoms may show up from time to time. When this happens, managers first look for the root cause which is often buried among multiple … Continue reading “12 Symptoms You May Not Know Are Connected”

Seasonal and Unbalanced Scheduling: A Case Study

Operation Managers and Human Resource Managers know that if your workload has seasonality, then you need a plan to deal with it. Maybe your strategy is to maximize gains or maybe its to minimize lost opportunities. Whatever your priority is, we can help you develop a staffing and scheduling strategy to achieve it. The case … Continue reading “Seasonal and Unbalanced Scheduling: A Case Study”

When should your shifts start?

As a Plant Manager or Human Resources Manager, in a shiftwork operation, you’ve certainly heard “Everyone that I know wants to start the shifts at such-and-such a time.” You hear this but the question is – What do you do about it? Should you survey the workforce and let them choose? Do you have your … Continue reading “When should your shifts start?”

Is Your Shift Schedule Lean?

There are many aspects to the concept of Lean Manufacturing and Lean Thinking. One of the fundamental goals of applying lean concepts is to eliminate waste in the process. What can we do to minimize waste in shift schedules? In no specific order, here are some places to look: Match the coverage to the workload … Continue reading “Is Your Shift Schedule Lean?”

Workforce Scheduling for Food Manufacturing

Managers of Food Manufacturing operations, you have some very unique challenges that are often not a concern in other types of manufacturing operations. These are typically issues surrounding seasonality, sanitation, and product mix. At Shiftwork Solutions, we know how to help you design a shiftwork structure that maximizes your production capacity in spite of these … Continue reading “Workforce Scheduling for Food Manufacturing”