Is overtime a good idea or a bad one. Ask as Production Manager or a Human Resource Manager this question and you may get different answers on different days.

Production Managers often need overtime just to get the job done; an immediate source of skilled labor that saves the day. This magic pill, however, can come with a price. Human Resource Managers will start to notice problems with retention, safety, and overall morale. Production Managers will see drops in productivity.

Understanding overtime is the key to controlling it.

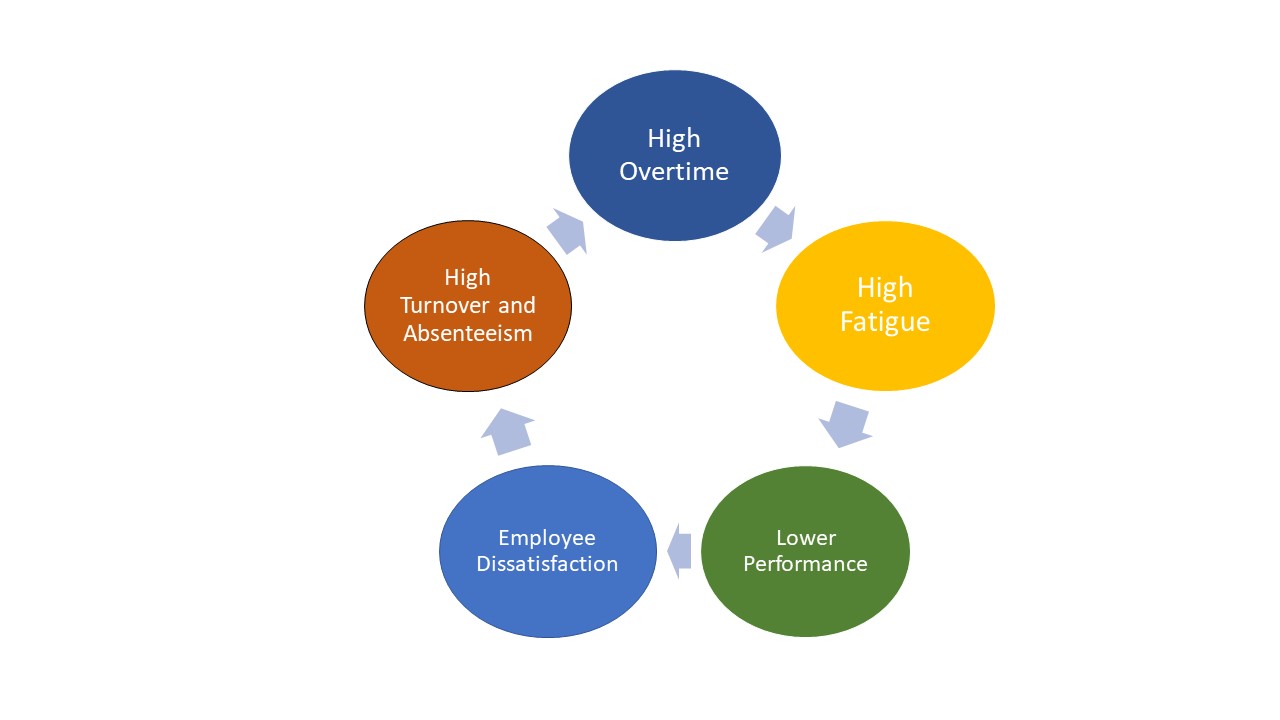

Overtime enables you to effectively manage higher workloads without increasing staffing levels. It also provides your employees with a source of supplemental income without having to spread their loyalty to other employers. When used properly, overtime can become a very powerful tool for meeting workload demands while minimizing costs and maximizing employee compensation and satisfaction. However, overtime that is out of control can lead to higher costs, lower quality, low employee morale and increased employee turnover.

The Source of Overtime

Much more often than not, overtime is a function of staffing. Too few people will cause overtime to rise. This condition usually arises with companies that are outgrowing the size of their current workforce or, have a “variable” workload that causes a fixed number of employees to be either “too many” or “too few”, depending on where they are in the cycle. A carousel at the bottom of this page has several blog posts addressing these issues.

The Benefits of Using Overtime

You probably already recognize the benefits of using overtime. They include:

- Overtime can be increased and decreased to match the labor resources to workload demands.

- Personnel working on overtime do not require additional training.

- Staffing levels do not need to change to use overtime.

- Overtime coverage is available on short notice.

- Most employees want to work some overtime to supplement their income.

The Problems with Using Overtime

While there are benefits to using overtime, there are also potential problems:

- High overtime levels can result in lower morale and decreased productivity.

- Prolonged, high overtime levels can result in the workforce becoming dependent on the overtime to make ends meet. Reducing overtime in this situation can be financially devastating for the workforce and lead to deteriorating employee relations.

- Overtime is expensive

…or is it?

At first glance, overtime does appear to be expensive. The combination of paying overtime at a premium (usually 1.5 x straight time, but sometimes at 2.0 or 3.0 x straight time), and working overtime hours that were not in the budget often results in negative overtime accounting variances. Since negative variances draw critical attention, managers often focus their energy on minimizing overtime.

Usually, the alternative to using overtime is to use personnel working straight time to perform the required work. While this is logical, straight time carries a premium of its own. Benefits such as insurance, vacations, and pensions are usually paid based on straight time hours worked. This causes the company’s cost of straight time to be higher than the average wage.

Figure 1 demonstrates that the incremental cost for using overtime instead of using straight time is, in fact, less than the 50% premium paid on wages for the overtime work. Since most companies have a benefit loading factor of between 30% and 40%, the incremental cost of overtime is usually between 7% and 18% more expensive than hiring personnel and using straight time.

For example, a company that has a benefit loading factor of 32% and an average wage of $15/hour would expect overtime to cost $2.40/hour (16% x $15/hour) more than it would have cost if the work was done at straight time. This point is taken off the graph at point ‘A’.

Since overtime is easily added or removed from the labor pool, it need not be used unless it is really necessary. Straight time hours, on the other hand, are part of the regular schedule. They cannot usually be reduced without reducing staffing (by reducing temporary employees or through layoffs or attrition of permanent employees). Therefore, covering all required hours can result in overstaffing and extremely expensive idle time.

Most companies find that overtime is the first, and least expensive tool available to match staffing requirements to a variable workload.

A Case Study

A recent Shiftwork Solutions client was experiencing high overtime levels in their manufacturing facility. The workforce was exhausted and costs were rising, while competitive pressures were shaving margins. The situation became acute for the manufacturing plant when the new sales forecast projected continued product demand growth. Working with plant management we found that:

- Product demand was seasonal, with demand levels 20% higher during the peak seasons – these peaks can be handled with overtime if other sources of overtime are controlled.

- The plant was 15% understaffed for the number of lines that needed to be run.

- Regional unemployment levels were very low, making recruiting personnel difficult.

- Productivity was hampered by weekly startups and shutdowns, obsolete equipment, and fatigued employees.

The Solution

In this client’s industry, continuous operations were the norm – eliminating costly losses due to unnecessary startups and shutdowns. Operating the plant continuously and implementing the best shiftwork solution had the following results:

- Increased the scheduled capacity of all available lines by 40%.

- Allowed the most modern and productive lines to handle the growing product demands.

- Idled obsolete lines for the majority of the year, while keeping them available for peak demand periods.

- Improved employee productivity relieved the pressure to hire additional personnel.

- Because productivity improved, staffing requirements were lowered and the need for unscheduled overtime was minimized- unscheduled overtime was once again a relief valve for addressing unusually high workloads.

- Unscheduled overtime costs were brought back within the budgeted levels.

Through extensive interaction with the workforce, a continuous shift-work solution was implemented that allowed employees to:

- Increase their guaranteed compensation by 7.5% with built-in overtime while increasing payroll costs by only 1% — this increased cost was paid for many times over by the improved shift-work solution.

- Increase their days off from 104/year to 182/year.

- Work a schedule that they felt best met their personal needs while keeping the company competitive.

The business bottom line was an improved product cost structure without significant capital investment using a shift-work solution chosen by the employees.

Call Us and let us help you get your overtime under control.

Call or text us today at (415) 763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.

So Good 👍