The number one way that companies find a shift schedule is to hold a meeting and ask, “So, does anyone know of any shift schedule patterns?”

There are several false assumptions built into this methodology. One is that all schedules are created equal; that any schedule that covers the hours needed is as good as any other schedule. Another is that the workforce, having been allowed to choose between a couple of patterns will be satisfied that their needs have been considered. Also, there is the one-size-fits-all idea which says that if one area goes to a 24/7 schedule (for example) then all other areas must follow suit. There is the staffing assumption that you must staff to allow for ZERO overtime and that all areas of the operation must increase or decrease staffing levels in lock-step; that is to say, if a new schedule covers 40% more hours you will need 40% more employees across the board (including supervision, quality, maintenance, etc.) Finally, there is the assumption that policies for things such as holidays and vacations, which worked for your old schedule, will also work for your new schedule.

There are actually many, many more issues that are overlooked or swept under the carpet in the name of expediency, but I think you get the picture.

The right schedule is one that is implemented using the old carpenter’s adage of “Measure Twice and Cut Once.”

Taking the time to do a schedule change right will not only save you from problems down the road but will likely result in immediate productivity gains and cost decreases which are not realized by the “Who knows a schedule pattern” methodology.

Here are my thoughts on just a couple of the “assumptions” mentioned above.

Employee participation is more than just allowing them to select between a couple of patterns. Participation means they know why a change is taking place. They are educated about what schedules can do (and can’t do). They are given a wide variety of options that span the range of what is available instead of just a few similar patterns. They are allowed to have meaningful input on things like overtime levels, start times, the day on/off patterns and more. They are given “perfect” information about their final options in such a way as to allow them to discuss the options with their families before making a choice.

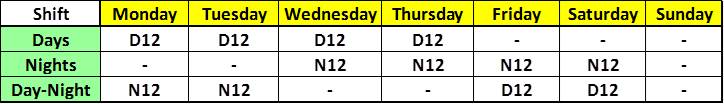

One-size-does NOT-fit-all: You may have an operation that absolutely needs to go to 24/7 (for example). In some cases, this means a “balanced” schedule across all days of the week where every day has the same number of people in production. However, suppose one or more areas can keep up with the 24/7 production by only running one shift a week; should they go to the 24/7 schedule? What about maintenance? Should they have a “balanced” schedule or should the labor be moved to parts of the week that maximize production? Remember, maintenance is at its peak performance when production is at its lowest. (It’s hard to fix equipment while it is running.) What about quality, engineering, and office staff? These areas rarely need to go to a 24/7 schedule (in their entirety) when production does.  The “Best Schedule” is usually a collection of schedules that allow all areas to operate and support each other seamlessly.

Staffing is where most companies make the most costly mistakes. They either over-staff and thus, pay for labor they don’t need or they under-staff and run the risk of high fatigue and turnover that typically come with a worn-out workforce. Staffing is not guesswork. There are mathematical solutions that will tell you what the optimal staffing level is for your site.

As for policies, let me just say this: “If you think your 5-day policies will all work just fine on a 24/7 schedule – you are wrong.”

If you decide to “go it alone” let me at least offer you this: Give me a call when you get stuck. So long as I don’t have to pick up a pencil, I’m free. So don’t make a mistake because you didn’t have someone to go to.

Call Us and We Can Help

Call or text us today at (415) 763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.