5 Common Mistakes to Avoid in 24/7 Operations – What the Employee Surveys Reveal

Managing a workforce across different shifts on different days and times – poses unique challenges in a 24/7 operation. From communication hurdles to maintaining a healthy work-life balance, the intricacies of overseeing diverse schedules require a nuanced approach. By understanding and addressing these challenges, managers can make a difference, helping their company to foster a more balanced and productive work environment. Our employee surveys, based on extensive employee feedback, conducted at a wide variety of manufacturing companies point to five mistakes managers need to steer clear of in 24/7 labor-intensive, blue-collar environments:

- Ineffective Communication Across Shifts: Data from our employee surveys consistently reveal that poor communication, at various levels, is a major concern among shift workers. This aligns with our observation that companies with low communication scores tend to have lower employee satisfaction levels. Inadequate communication can often foster resentment, frustration, and disengagement, which can have far more detrimental effects on the work environment than commonly perceived. When addressing communication issues, the focus often centers on “what” and “how” information is conveyed. However, the things that are not communicated can have just as much impact on shift workers. For instance, the lack of response regarding vacation requests, the absence of follow-up on previously discussed issues, or the failure to provide feedback on reported safety incidents can significantly impact employee morale. Detecting the absence of effective communication can be challenging. However, we’ve observed that supervisors who actively engage with their teams and maintain a consistent presence on the floor are less likely to encounter such issues. Supervisors, who consciously make themselves accessible for open communication, foster two-way dialogue instead of one-sided monologues, and proactively seek feedback can effectively bridge communication gaps and elevate morale on the shop floor – cultivating a more positive and productive work environment for their shift workers.

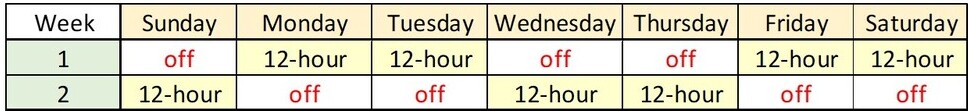

- Downplaying the Importance of Schedule Flexibility: Schedule flexibility can have varying interpretations for different audiences. For shift workers, two recurring yet opposing concerns emerge (1) Inability to take time off: shift workers often express frustration with the rigidity of their schedules, limiting their ability to take time off when desired. (2) Limited Overtime Opportunities: Conversely, some shift workers desire additional overtime hours to supplement their income but find their schedules restrictive. The solution to both concerns lies in optimizing staffing levels. Having too few staff members leads to excessive overtime, while an overabundance of personnel can be costly to the company and potentially disappointing to those employees who rely on overtime opportunities. Understanding both the financial implications and employee preferences for overtime is crucial for determining the ideal staffing level. By striking a balance between these considerations, companies can create a schedule that accommodates both employee needs and organizational goals.

- Missing the Mark on Training: Despite managers believing they train shift workers adequately, our surveys reveal a common disconnect: workers desire more. While companies invest considerable effort in developing and delivering training programs, employees often feel their training is not focused on what is most important to them. These individuals, embedded within the daily operations and directly interacting with the production line, co-workers, and equipment, possess valuable firsthand knowledge of training deficiencies. By actively seeking the insights and perspectives of their shift workers, managers can address this disparity and can gain a clearer understanding of the workers’ unmet training needs. Combining surveys, interviews, and direct observation is an effective way to tailor the training curricula, ensuring that the content is relevant, engaging, and addresses the specific needs of shift workers.

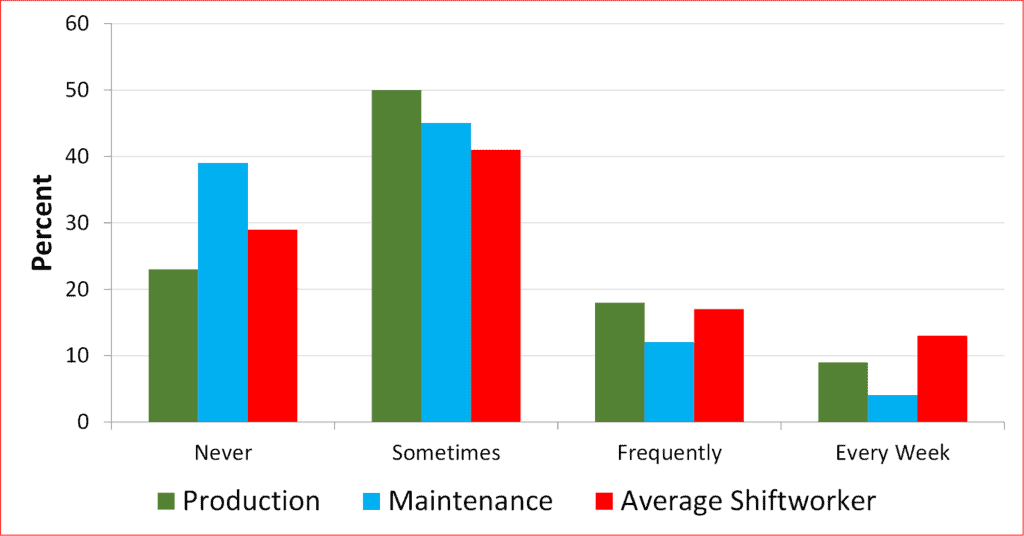

- Failure to Publicly Recognize Good Performance: Employees consistently tell us that being publicly appreciated for their efforts is crucial for their job satisfaction. Higher job satisfaction is often linked to higher employee engagement levels, more profits, and lower employee turnover. It is worth paying attention to and requires little investment. Companies have numerous options for public recognition, including verbal acknowledgment (during team meetings, safety talks, and casual conversations), and company communication channels such as digital displays, awards, and celebrations. Online nomination platforms and even shift handover reports can be utilized to ensure that recognition continues for differing schedules. Appreciating specific actions and behaviors motivates others and reinforces desired conduct. Personalized and regular employee recognition is a valuable investment that can yield numerous benefits for all stakeholders involved.

- Underestimating the Value of Workforce Input: A purely “top-down” management style works in some environments but in most, it can lead to missed opportunities that lie within the knowledge base of the workforce. To successfully manage a workforce, seeking input directly from employees is key. Their firsthand experiences and unique ideas about shiftwork, schedules, and work-life balance provide valuable insights, enabling managers to understand and address what is truly important to the workforce. By creating a culture where workers feel valued and respected, companies can reap significant rewards in terms of increased productivity, creativity, and innovation.

Juggling a successful operation while managing shift workers in a complex environment can be tough, but understanding common pitfalls is key to building a better workplace and a thriving business. Clear communication, flexible schedules, thorough training, appreciation across all shifts, and empowering employees through their input – these are the ingredients that help managers navigate the unique challenges of shift work, creating a space where productivity thrives around the clock.

What would your workforce say? Contact us today to schedule a free consultation and discover how we can assist you with shaping a positive work environment, improving productivity, and sustaining a prospering business. Shift to success!