This post is the third in a series about 10-hour shifts. If you have not already seen the first two posts in this series, I recommend you do so before viewing this post.

Author: Jim

10-hour shifts – Part Four

This post is the fourth and final post in a series about 10-hour shifts. If you have not already seen the first three posts in this series, I recommend you do so before viewing this post.

Management By Walking Around

Plant managers and Human Resource managers, if you want to make your job a bit easier, take a walk.

Every site I go to the number one issue is “How can we get the people we need to produce at the level we need to produce?”

A facility struggles to find and keep qualified people and then a competitor opens the doors across the street.

What to do.

The short, and expensive answer is to raise wages. Â Not just any wages; you need to raise entry-level wages if you are looking to attract more employees. Â You need to raise all wages if you want to keep employees.

This is Wage Economics 101.

We can get caught up in the “wages solve everything” train of thought but then we lose track of the fact that wages are not the only reason people come to work for you.

This brings me to the subject of this post: Management by walking around.

I was recently at a manufacturing facility where they were struggling with getting people in the door. Â There was a lot of local competition for the same level of the worker within a 20-mile radius.

This particular site was paying wages slightly below the median level. Â This understandably made it hard to compete for new employees. Â However, this company was having very little trouble retaining existing employees; employees that knew they could make more money for similar work just a mile down the road.

I was curious about this and went about interviewing people as to why they liked working there. Â Overwhelmingly the answer was: “I like the people I work with.” Â Nine out of ten gave this as their primary reason for working there.

Now, add to this equation, the plant manager; a young, very bright and energetic man. Â He took me on a tour and introduced me to everyone we met. Â He knew their first names. Â He knew how many children they each had. Â He knew who was in school. Â In short, he knew everything about the 200 employees there as if they were his friends.

And that’s how he treated them.

It was clear that he was in charge. Â If he saw a leak, he’d point it out to maintenance and they got after it. Â If a machine was having a problem, he’d ask the operator what he, the Plant Manager, could do to help.

There was mutual respect across the board.

This manager spent a lot of time on the floor. Â Mostly, I think, so that his people would see him seeing them. Â His presence never had the feel of an inspection. Â Rather, he was there to help them do their jobs. Â The employees were working hard, but not for some unseen boss behind a closed door. Â They were working for the man in the smile that knew them as if they were family.

This was a great place to work and enjoyed my time there.

It all started with the Plant Manager. Â His positive attitude moved down through the ranks until the newest hire felt like he was an important part of what was going on around him.

Yes, wages are a big player when it comes to attracting and retaining quality employees. Â But remember, its not the only game in town.

Call Us and let our Employee Engagement process help to open up the lines of communication between the production floor and upper management.

Call or text us today at (415)763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.

Best Practices

I am often asked about Best Practices in a shiftwork operation. In this post, I’ve listed 50 of those practices. I want to stress that every environment is unique. Best Practices are not. What works best at one site may not be applicable to another.

- Avoid rotating shifts.

- Don’t start earlier than 6:00 am.

- Pay 10% to 15% shift differential for non-day shifts.

- Don’t pay weekend premiums.

- Don’t use a weekend crew.

- Operators and Sanitors should be the same people.

- Do not overstaff.

- Listen carefully for the term “unfair”.

- Perception matters more than reality.

- 20% of your workforce will work all the overtime you can give them.

- Don’t assume a 15-minute change in shift times is “no big deal”.

- Continuous schedules can be much more attractive than non-continuous.

- Cross-training does not mean everyone can do everything.

- Temporary workers cost less and are generally even less productive.

- In times of low unemployment, labor is the Cost Maker.

- It takes an order of magnitude greater effort to recruit from another plant than from the ranks of the unemployed.

- 5% of your workforce will complain regardless of what you do.

- There is no such thing as over-communicating.

- Try to never stop or start anything…that’s when it will break.

- When it comes to overtime, predictability makes it less painful.

- Actively look for ways for the workforce to make decisions about their job. They will own the result.

- Your employees want to “see you see them” working on off-hours and weekends.

- People don’t like to be told what to do.

- Overstaffing is the most expensive labor option.

- Do not underestimate the value of strong first-line supervision.

- Don’t pay for skills you don’t use.

- Poor distribution of overtime can cause more problems than overtime itself.

- Customers drive demand and thus, production levels.

- No matter how much maintenance you think you need, you are wrong. Plan for that.

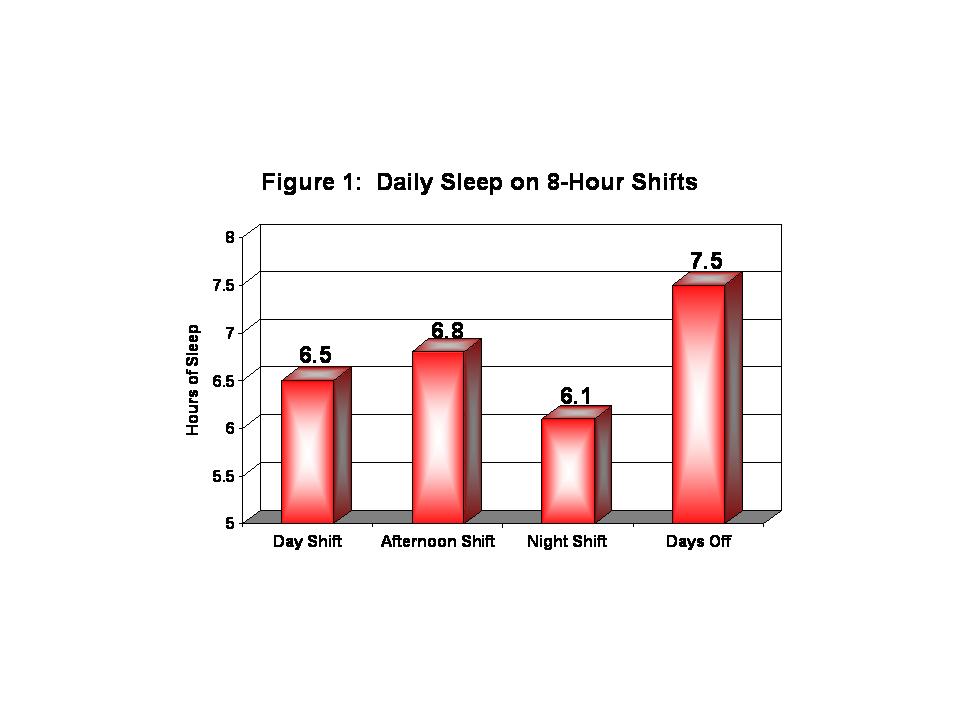

- Sleepiness will harm production, quality, and safety.

- To attract employees, you need not be perfect. You just need to be their best option.

- The combined intellect of any workforce is greater than any one person.

- Public recognition of a job well done is important.

- When a team walks out of a meeting, they all own the decision that was made inside.

- Risk empowerment. It will surprise you.

- You can only expect what you can inspect.

- Seasonality variations require creative solutions to scheduling.

- As far as cost is concerned, Straight Time and Overtime are probably within 5% of each other.

- Whenever possible, do the math first.

- Coach when you can, direct when you must.

- Walk in the shoes of those that work for you to find out how they see things.

- Don’t change for the sake of changing something.

- Shoot the wolf closest to the sled.

- 20% of your workforce wants no overtime at all.

- Supervision should match the schedule of those they supervise.

- Give shift workers at least 4 weeks’ notification before a major schedule change.

- Expect a schedule change in one department to impact the schedule needs of another department.

- Managers judge a schedule by its coverage. Shift workers judge a schedule by its time off.

- Understand the exact cost of your labor options.

- When changing schedules, be prepared to change policies to match.

This list could go on and on. If you have any to add or would like to discuss any of these, give us a call.

Call Us and We Can Help

Call or text us today at (415) 763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.

An Introduction To Optimal Staffing Levels

The most important factors determining optimal staffing levels.

Non-wage Solutions to Rising Wage Pressure

Human Resource managers: How can you attract a quality workforce when you know that doing so with wages is out of the question?

Back when we were recovering from the Great Recession, we all knew this was coming. We watched and cheered as unemployment numbers dropped, month after month. This meant the economy was recovering. Manufacturing, in many industries, has reached the tipping point and is returning to the United States at a pace not seen in decades.

One of the results of this “bountifulness” is a lack of skilled labor. In some cases, it’s a lack of labor at even the most basic levels.

Part of this is a training issue. We have modernized our production methods without a training mentality to keep pace with the new skills we need. Part of this is just “not enough bodies.” The result is a scarcity of labor which drives up the cost of labor as we compete for this ever-dwindling resource.

The most obvious way to deal with this; to bring in the labor with the skills you need; is to raise wages. Raise that wage bar high enough and labor no longer becomes a problem. However, you have now changed your cost structure and thus your profitability. In some industries, labor costs are a small component of the Cost of Goods Manufactured and increased wages have relatively little impact. In other areas, labor costs eat away at a small profit margin and your very survivability depends on your keeping these costs low.

So, what can you do if you don’t want to, or don’t have the ability to raise wages?

The answer is to use your schedule as part of the attraction. Make it one of the reasons people want to work for you and not the company across the street.

Here are just a few ways to do this:

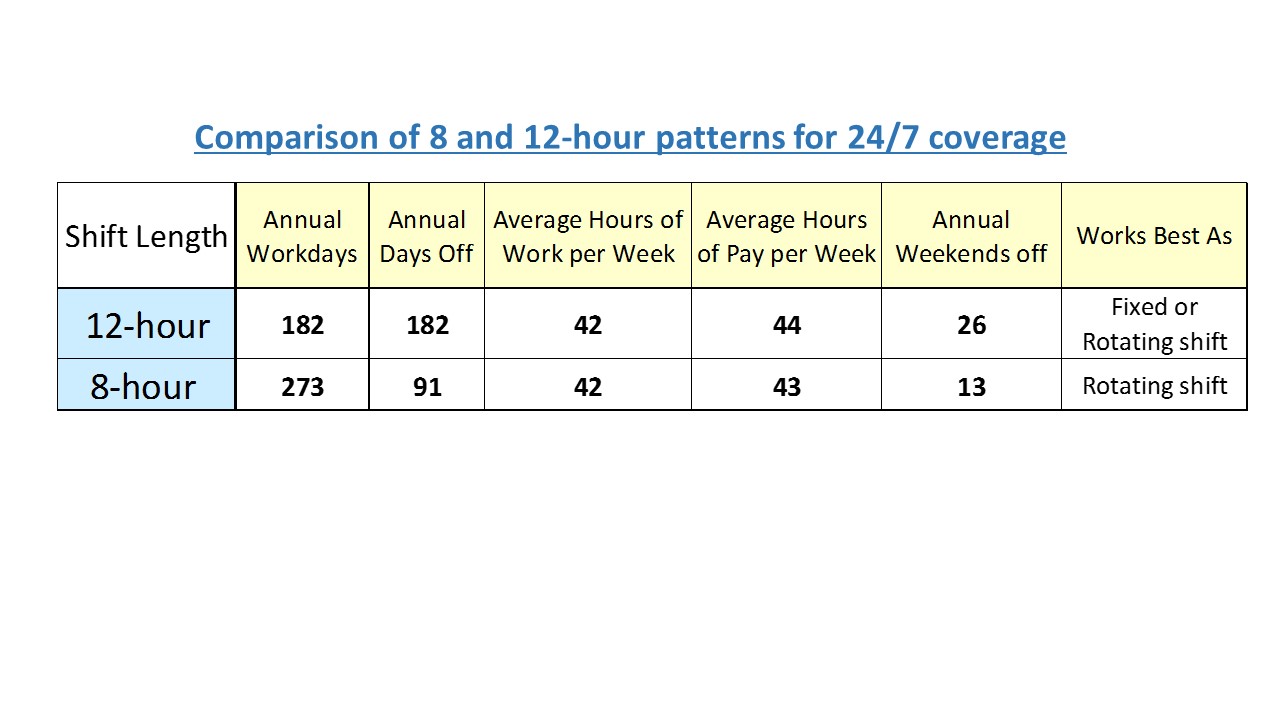

- Maximize days off. The overwhelming preference of our labor force is to work longer days to get more days off. As an example, let’s assume an employee works 40 hours a week or 2,080 hours a year. If they work 8-hour days, they will have to work 260 days a year. If they work 10-hour days, they will have to work 208 days a year. If they work 12-hour days they will have to work 173.3 days per year.

- Make your work schedule one that fits the needs of your employees. Don’t assume you know what your workforce wants. Ask them. Ask them in such a way as to allow everyone to participate. This means creating a setting where the “loud cannot intimidate the meek.”

- Make your work schedule predictable. This means creating a system where your employees know when they can work and when they can plan on not being at work.

- Look at flex-time or work-from-home ideas. There is little doubt that employees find these types of ideas attractive.

- Use overtime as a benefit. This means finding out how much overtime your workforce wants as well as who wants it and who does not. You want to be able to get overtime to those that like it while not forcing it on those that don’t. This will improve predictability as well as help you to compete wage-wise. A company across the street may pay $15 an hour while you only pay $14. However, if you offer a lot of overtime, your overtime employees will recognize that they can make a lot more money working for you. Along with making overtime available, try to absolutely minimize the number of times overtime is “mandated” or assigned on short/no notice.

- Create a participative work environment. No one likes to be told what to do. When I go to a site and find the workforce somewhat disgruntled, it is nearly always a communication issue. More specifically, it’s a feeling of “I don’t matter” or “No one is listening to me.” Keep in mind, people come to work for the money but stay for other things such as job recognition, the ability to advance and a feeling of accomplishment.

- Make your actions and policies transparent and apply them fairly. All too often, I come across employees who misunderstand a policy or feel they are being singled out. When this happens, it is important to listen and investigate. They might be right. Or, they might be wrong but are just seeing things incorrectly. Feelings of “not fair” are precursors to an employee leaving for greener, more just, pastures.

The right schedule choice can help keep costs and attrition low and employees engaged. Asking the workforce about their preferences, however, has the utmost importance and so does the way you manage and communicate the change and keep up the participative work environment.

Call Us and so we can help you compete for labor in an increasingly tight labor market.

Call or text us today at (415) 763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.

Why is changing schedules so difficult?

Companies are often surprised at how difficult changing a shift schedule can be.

There are several reasons for this but the big two are:

- Employees are familiar and thus comfortable with their current schedule while something else represents an unknown. To an extent, we all fear the unknown.

- A schedule is very personal to those that work it. It tells them when they can go on vacation, when they can pick up their kids and when they can coach sports. Even a small change in the schedule feels like a company has stuck their hand into a shift worker’s private life and stirred things up.

There are other, less dominant issues as well. Maybe two spouses are on different schedules and they have things worked out so that one is always at home and thus, no money is needed for daycare. Maybe a shift worker is also a student and a new schedule will cause them to miss classes. Maybe there is misinformation about the new schedule – someone that doesn’t want change is spreading the false narrative that “Overtime will go up” or “People will be laid off.”

The best way to address the resistance is a combination of education and participation.

If people knew exactly what they were getting into, the change would be easier. If the change represented shift worker input so that it minimized unwanted disruption to their personal situations, change would be easier. If shift workers understood the need for a change as well as how it could personally benefit them, the change would be easier.

Call Us and We Can Help

Call or text us today at (415) 763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.

Be Careful What You Ask For – Part One

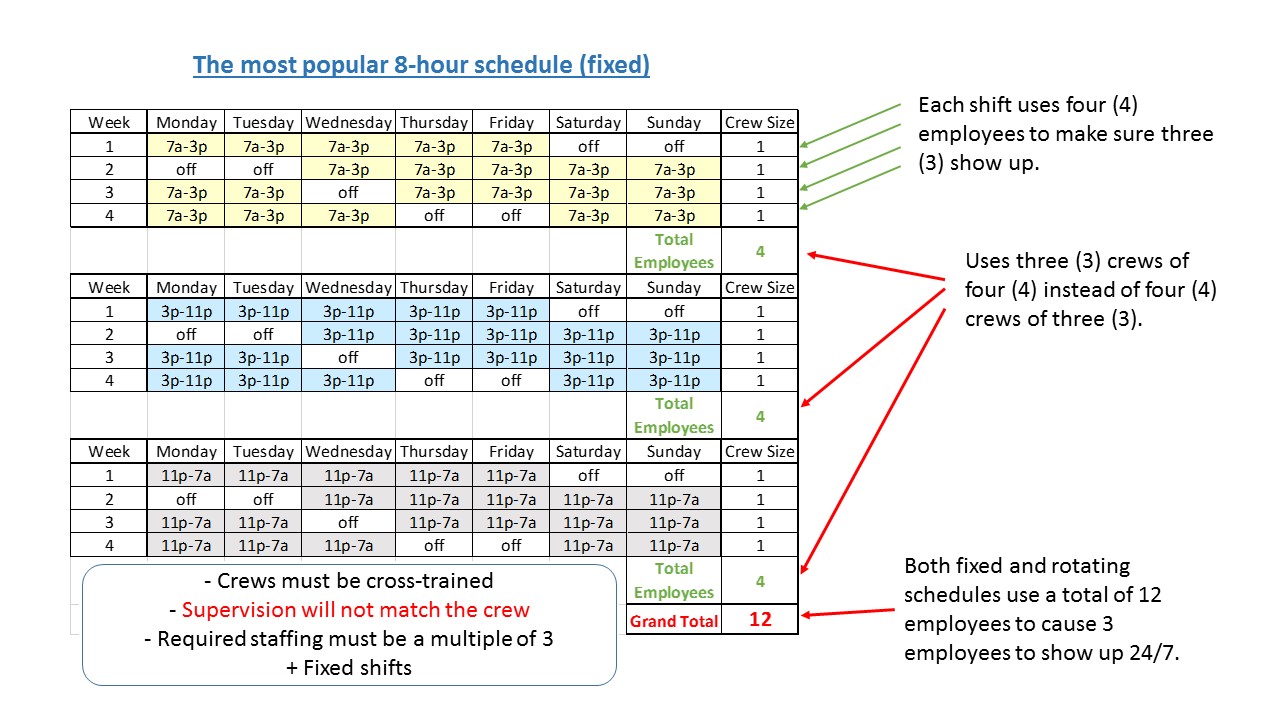

Once upon a time, about 28 years ago now, nearly every 24/7 operation in the country was using some version of a rotating 8-hour schedule. Ten years ago, when I asked large groups of employees if any of them have ever worked one of those outdated 8-hour schedules – inevitably, several hands would go up.

Today, if I ask…no one remembers that schedule. People are no longer going to 12-hour shifts and saying “Thank God that 8-hour rotating beast went away.” Instead, they are born into 12-hour shifts, with no knowledge of what the old schedules used to look like.

So, what are workers wishing for now? They are saying “12-hours is too long to work. I want to go to an 8-hour schedule.” They say this thinking that they will somehow reduce the length of the shift and not have to go to work 50% more days of the year. They don’t know that they are really asking to give up half of their weekends. The certainly don’t know that they are asking to give up their fixed shifts for rotating ones.

The cure for this is information. When your workforce brings up the “shift is too long” issue, all you need to do is make sure they completely understand what the alternative is.

While I have never had anyone tell me “I love being at work for 12 hours,” I also have never had someone say “I really want to work more days for less money and fewer weekends off while rotating through all the different shifts every four weeks.”

Here are a couple of charts that will hopefully help to demonstrate what you are getting into with 8-hour shifts. I use the most popular 8-hour 24/7 pattern there is. In the example, I use 12 employees to make 3 show up 24/7.

Call Us and We Can Help

Call or text us today at (415) 763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.

How many people does it take to staff your schedule? (Part 2)

There is a short answer and a long answer to this question. Here is a link to the short answer.

As for the long answer:

Take a look at the “short answer” in the previous blog post. That is a good place to start.

The following should be considered to refine the number you get using the “short answer”:

- The cost of full-time labor matters. How much does it cost you to pay someone for an hour of straight time? How much does it cost you to pay for an hour of overtime? I am not talking about “how much an employee receives.” I’m talking about cost-to-the-company. If you do the analysis correctly, you should find that the two costs (overtime and straight time) are within 10% of each other. This is important because the amount of overtime you use will play a big factor in staffing levels. For a fixed workload, the higher the overtime, the lower the staffing level you need.

- How much training does it take to qualify an employee for a position? It is likely that there is a wide variance in this with regard to different positions. Do Not use and “average”. If you need an astrophysicist and a box stacker, an average will give you a bad number (4 years of post-graduate study for the physicist and 5 minutes for the stacker = about 2 years, on average, to train an employee). Long training times lead to increased use of overtime and less reliance on other labor options such as temporary help. If your workforce is staffed with highly skilled people, whose skills are easily transferable to another nearby company, then you will have to bend a more towards compensation scheduling and employee preferences for overtime so as to not lose these people.

- How variable is your workload? If your workload level is flat, you will still have some fluctuations in staffing as people are on vacation or FMLA, etc. When staffing fluctuates, you have extra staffing available or you can use overtime or you can reduce production. Cost, degree of variability, employee preference and the nature of your operations will all play a role in determining how you staff for variability.  It’s worth noting here that the most expensive option is to over-staff or staff for peak production as this leads to frequent over-staffing which is costly. A highly variable workload tends to mean lower staffing and higher overtime.

- How available are alternative sources of labor? Is your workforce pro-overtime or overtime-adverse? Is temporary or part-time labor available? If you are in Memphis and need temporary, highly skill forklift drivers, there are temp. agencies that can give you all this type of labor that you want. However, if you need those same temporary skills in San Francisco, you may need to “grow your own.” Can you scale back with seasonality by using shorter workweeks or voluntary layoffs? Note: If the answer is no, the staff to the lower end and use overtime when things get busy.

- What about support activities? Things like maintenance, engineering, quality shipping/receiving and administration all need to be staffed appropriately as you grow (or shrink). There is no simple formula for how to staff these as there is often not a “straight line” relationship between staffing numbers in operations and staffing numbers for support areas. For example, a 30% increase in operation staffing does not mean you need 30% more CFO’s. In some areas, you may actually find that you need less support staff. For example, maintenance struggles to fix everything on the weekend but if you go to a 24/7 schedule, maintenance can now take place any time in the week; including weekdays where it can be performed more efficiently.

- Are you LEAN? It’s “old school” to think you should stockpile between cells in a value stream to ensure you never run out of product either upstream or downstream. Instead, just-in-time is what modern operations strive for. Many companies can maximize or throttle production using staffing alone.  This may mean you staff an area below its maximum capacity to ensure it does not outrun its value stream neighbors.

- What is the opportunity cost of lost time? This must be a consideration if you are going to staff with as few people as possible. You may save a lot of money by having fewer maintenance specialists but then you might lose even more money if you suffer downtime because you are understaffed.

Call Us and We Can Help

Call or text us today at (415) 763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.

Knowing the Unknown

For the last 5 years, much of the work that we, at Shiftwork Solutions, have been asked to perform, has been centered around Work-Life Balance.

The reason for this is clear – Low Unemployment.

Shiftwork operations tend to have a lot of employees.  Since this particular resource is scarce during periods of low unemployment, companies are scrambling to find ways to attract and retain a quality workforce. There is always a sense of urgency to this effort as companies want to “Get new employees on board before they start somewhere else.” The reason for this is that it takes an order of magnitude greater effort to recruit from another company than it does to recruit from the ranks of the unemployed.

Companies are getting very creative. They have job fairs. They have signing bonuses. They implement multiple schedules so they can offer a “menu” for prospective employees to choose from. They are increasing wages. They are implementing employee empowerment programs.

What strikes me is that many companies are making decisions about their workforce with less information than they need in this regard.

As an example, let me talk about a company I worked with recently.

They are a successful and rapidly growing company with about 400 hourly workers at their site. They were having a lot of trouble hiring enough employees. Orders were falling behind and market share was at risk.

I was brought in to install a shift schedule that would fix this.

My first questions were: (1) What does the workforce not like about the current schedule? (2) Where is your pay with regards to nearby companies seeking a similar quality of worker? (3) What are your current production needs as well as what will they be going forward? (4) What is the difference in productivity between a new hire and a seasoned employee?

Of course, there were several more questions, but these were the ones I want to use in this example.

Understandably, the company knew that it could only speculate about how the workforce felt about their schedule. At Shiftwork Solutions, we are equipped to gather this type of information through a program of employee education and participation.

The pay was middle of the road. Some nearby companies paid more and some paid less.

Production demands were going to slow to a 10% growth rate; still significant but lower than the 30% growth rate from previous years.

And here is the biggie: A seasoned employee could perform an assembly step in 8 minutes where a new employee, after weeks of training, would do the same step in 12 minutes.

After a few weeks, I presented my results.

Overall, they were very positive. The employees viewed the company in a very positive light in nearly every examine category.

The exception was pay. The workforce felt underpaid. At this point, it’s important to remember that “perception is everything.” By this I mean, it doesn’t matter if the workforce is underpaid or overpaid. What matters is what the workforce perceives to be the case.

There were some schedule issues to be fixed that would improve the work-life balance of the workforce. However, these fixes were not a major finding. They would help with recruitment and retention but they wouldn’t solve everything.

To do that, the company would need to go after the elephant in the room – pay.

Using intuition, most people felt that increases in pay would increase costs. This was a major concern as some competitors were from low-wage countries and were seen to have a cost advantage as a result.

So, during my presentation, I asked the following 2 questions to the management group:Â (1) How much would you have to increase wages in order to stop attrition and ease recruitment? and (2) If you had a stable, skilled workforce, how much of an improvement would you expect in the “step time” per assembly station?

The answers were: (1) We would need to increase the hourly rate by 30% and (2) A stable workforce would give a 30% increase in productivity.

Using a sensitivity analysis prepared in advance, I first increase pay by 30% and showed that this would increase per-unit costs by 3-4%. Next, instead of increasing productivity by 30%, I increased it by a modest 10%. When I did this, the per-unit cost dropped by more than 25%!

This was a surprising result. It showed that a huge rise in pay combined with a modest increase in productivity would have a tremendous impact on lowering per unit production costs.

Now we had the information we needed. By getting the workforce involved and doing the math with regards to the business, we were able to make decisions that would produce the outcomes we expected.

Call Us and We Can Help

Call or text us today at (415) 763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.