For the last 5 years, much of the work that we, at Shiftwork Solutions, have been asked to perform, has been centered around Work-Life Balance.

The reason for this is clear – Low Unemployment.

Shiftwork operations tend to have a lot of employees.  Since this particular resource is scarce during periods of low unemployment, companies are scrambling to find ways to attract and retain a quality workforce. There is always a sense of urgency to this effort as companies want to “Get new employees on board before they start somewhere else.” The reason for this is that it takes an order of magnitude greater effort to recruit from another company than it does to recruit from the ranks of the unemployed.

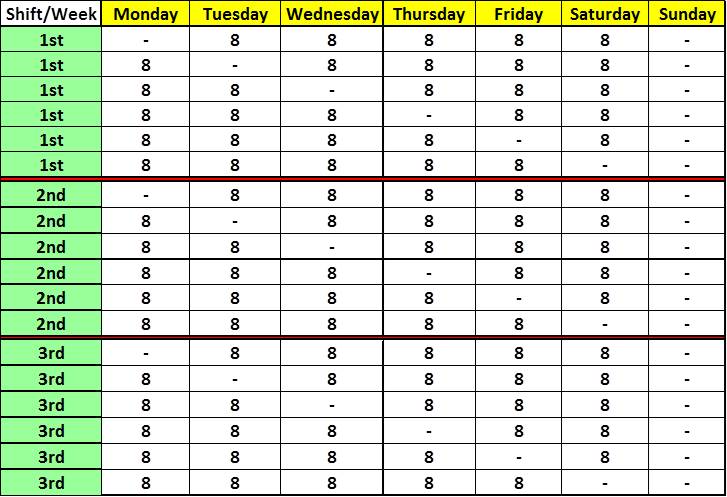

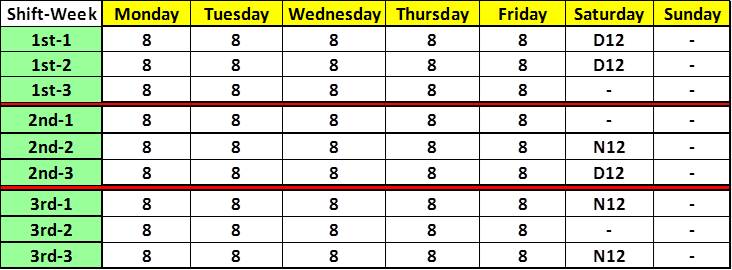

Companies are getting very creative. They have job fairs. They have signing bonuses. They implement multiple schedules so they can offer a “menu” for prospective employees to choose from. They are increasing wages. They are implementing employee empowerment programs.

What strikes me is that many companies are making decisions about their workforce with less information than they need in this regard.

As an example, let me talk about a company I worked with recently.

They are a successful and rapidly growing company with about 400 hourly workers at their site. They were having a lot of trouble hiring enough employees. Orders were falling behind and market share was at risk.

I was brought in to install a shift schedule that would fix this.

My first questions were: (1) What does the workforce not like about the current schedule? (2) Where is your pay with regards to nearby companies seeking a similar quality of worker? (3) What are your current production needs as well as what will they be going forward? (4) What is the difference in productivity between a new hire and a seasoned employee?

Of course, there were several more questions, but these were the ones I want to use in this example.

Understandably, the company knew that it could only speculate about how the workforce felt about their schedule. At Shiftwork Solutions, we are equipped to gather this type of information through a program of employee education and participation.

The pay was middle of the road. Some nearby companies paid more and some paid less.

Production demands were going to slow to a 10% growth rate; still significant but lower than the 30% growth rate from previous years.

And here is the biggie: A seasoned employee could perform an assembly step in 8 minutes where a new employee, after weeks of training, would do the same step in 12 minutes.

After a few weeks, I presented my results.

Overall, they were very positive. The employees viewed the company in a very positive light in nearly every examine category.

The exception was pay. The workforce felt underpaid. At this point, it’s important to remember that “perception is everything.” By this I mean, it doesn’t matter if the workforce is underpaid or overpaid. What matters is what the workforce perceives to be the case.

There were some schedule issues to be fixed that would improve the work-life balance of the workforce. However, these fixes were not a major finding. They would help with recruitment and retention but they wouldn’t solve everything.

To do that, the company would need to go after the elephant in the room – pay.

Using intuition, most people felt that increases in pay would increase costs. This was a major concern as some competitors were from low-wage countries and were seen to have a cost advantage as a result.

So, during my presentation, I asked the following 2 questions to the management group:Â (1) How much would you have to increase wages in order to stop attrition and ease recruitment? and (2) If you had a stable, skilled workforce, how much of an improvement would you expect in the “step time” per assembly station?

The answers were: (1) We would need to increase the hourly rate by 30% and (2) A stable workforce would give a 30% increase in productivity.

Using a sensitivity analysis prepared in advance, I first increase pay by 30% and showed that this would increase per-unit costs by 3-4%. Next, instead of increasing productivity by 30%, I increased it by a modest 10%. When I did this, the per-unit cost dropped by more than 25%!

This was a surprising result. It showed that a huge rise in pay combined with a modest increase in productivity would have a tremendous impact on lowering per unit production costs.

Now we had the information we needed. By getting the workforce involved and doing the math with regards to the business, we were able to make decisions that would produce the outcomes we expected.

Call Us and We Can Help

Call or text us today at (415) 763-5005 to discuss your operations and how we can help you solve your shift work problems. You can also complete our contact form and we will call you.