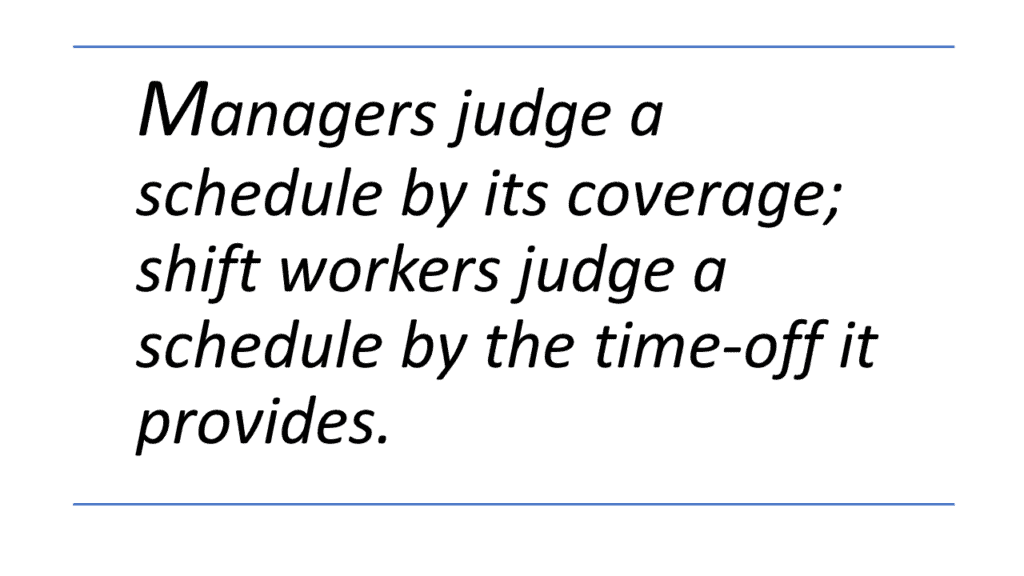

- Donât assume a 15-minute change in shift times is âno big dealâ.

Managers judge a schedule by âthe coverage it provides.â Shift workers, on the other hand, judge a schedule by âthe time off it provides.â In other words, they are looking at the type of lifestyle they can carve out around the time they are not at work. This makes the schedule very personal as it tells them when they can live the not-at-work part of their lives. When you change a shift start time by even a very small amount, it is a big deal. To shift workers, it will feel like you are reaching into their private lives and moving things around. Maybe, they can no longer pick up or drop off their kids at school. Maybe, they canât catch the same bus. Maybe, they will have to drop out of a church committee. All because of a seemingly small change.

2. Continuous schedules can be much more attractive than non-continuous ones.

If you ask just about any person on the street the following question, âHow would you like to work 12-hour workdays and give up half of your weekends off?â Probably around 100% would say âNo way!â

Letâs ask the same question a bit differently. âHow would you like to have 78 more days off a year. Also, how would you like 10% more income? Also, how would you like to be able to get off 7 days in a row just using 24 hours of vacation time? Also, how would you like to virtually eliminate unscheduled, mandatory overtime? Also, how would you like to work a schedule that greatly increases your chances of getting to a day shift?â

You will likely get a different answer. From time to time, Shiftwork Solutions helps companies go back to a 5-day schedule from a 7-day, continuous schedule. This type of project faces much more resistance from the workforce than going the other way; from a 5-day schedule to a 7-day continuous schedule. Why? Because they have experienced firsthand the benefits that you can only get from a continuous schedule.

3. Cross-training does not mean everyone can do everything.

Imagine you have a crew of 20 employees. Each person has a unique skill. Place them all in a circle and then decide, how much cross-training do you need to do to ensure that a new employee can join the group and ensure that your facility will still run no matter who is absent on any given day.

Often, the first response is: âEveryone needs to know how to do everyone elseâs job.â

The right answer is: âEveryone needs to know how to do their job as well as the job of the person standing to their left.â

Why is this so? Suppose, your nuclear physicist is on vacation and you need to fill that position somehow using a new hire that only knows how to stack boxes. That new hire will relieve the current box stacker who will relieve the label operator who will relive the filler operator and so on. Everyone gets bumped to the left (remember we started with them all in a circle.) Eventually, the assistant nuclear physicist is relieved and that person then steps in to fill the position of the nuclear physicist that is on vacation.

4. Temporary workers cost less and are generally even less productive.

When it comes to a lot of things, âyou get what you pay forâ seems to ring true. This is often the case with labor. Filling a position with temporary labor may mean that your labor cost per hour will be lower. It may also mean that your productivity per labor hour is lower as well. This is not always the case but it is worth paying attention to.

At a plant we helped solve productivity issues, temporary labor was about 75% the cost of straight time labor. Sounds like a great deal â until an investigation showed that a full-time employee was six times as productive in certain jobs.

There are a lot of times when temporary labor performance is indistinguishable from full-time labor performance. There are several reasons why using temporary labor is a great idea for your facility. But beware of the time-tested adage âyou get what you pay forâ.

5. In times of low unemployment, labor is the Cost Maker.

We tend to think that companies set their labor rate. While this is true, the company doesnât do this in a vacuum. Outside influences will determine the rate that the company decides to pay. If unemployment is high, say 10%, companies will find it easy to hire workers and fill positions. Every opening will have dozens of applications. However, if unemployment is low, say 5%, the tide will have turned. There is virtually no one that is looking for a job. You are left hiring those few that remain unemployed for some reason or, you are faced with the very expensive proposition of enticing someone to leave their company to come work for you.

To compete, you raise wages. Labor will go towards the highest bidder.

This is continued from Part 2 of Best Practices.

Find out how we can help you optimize your shift work architecture:

- Call or text us today at (415) 763-5005

- Complete our contact form and we will call you back

- Request a meeting by booking a time that works for you the best here.